Description

Rice Sheller Process:

Milling is a crucial step in the post-production of rice. The primary objective of a rice milling system is to remove the layers of husk and bran to produce an edible, white rice kernel that has undergone the necessary processing and is impurity-free. Rice shouldn’t contain any fewer cracked kernels than what the consumer needs. Visit Malik Agro Industries if you need a rice sheller or rice mill machine.

This rice shellar in united kingdom also has hulling and whitening capabilities. After the paddy is hulled, you can opt to discharge the brown rice immediately if you wish to manufacture brown rice. Additionally, a grinder is an optional addition that can be used to produce rice flour, rice husk feed, as well as other grains flour such as maize flour, sorghum flour, soybean flour, and millet flour.

A system for milling rice can use straightforward one- or two-step processes as well as multi-stage methods. A one-step milling process produces milled or white rice directly from the paddy by removing the husk and bran in one pass.In a two-step process, brown rice is produced as a byproduct after the removal of the husk and the removal of the bran are each completed independently.

During multistage milling, rice will go through a range of unique processing steps.

Depending on whether the paddy is processed in the village for local consumption or for the market, rice shellar in Sharjah techniques can be split into two groups: Commercial and village mills are the two varieties. Reach out to Malik Agro Industries for rice shellar machine near me and Maize Shellers.

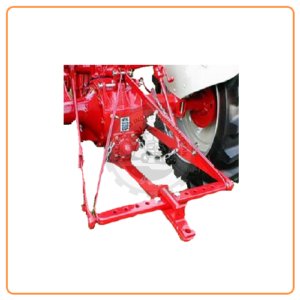

Features of a Rice Sheller Machine

- This rice mill machine can handle every type of rice, whether it is short or long, brown or white.

- The machine’s body has an electric motor fixed underneath, which can increase working stability.

- Include the little cyclone; it is useful for gathering rice husk.

- The ideal rubber roller interval is between 1-1.5mm, but this can be varied.

- It is simple for one person to use.

This little rice mill equipment, of course, does not include a paddy de-stoner. That implies you must clean your paddy of any stones, metal scraps, stalks, leaves, and other objects before using this machine to produce rice. Otherwise, these contaminants will harm it or compromise its functionality.

How Can We Utilise This Small Rice Mill To Effectively Remove Pollutants From Paddy?

Here, we suggest a compact detoner machine whose capacity matches that of this rice mill. This rice machine uses the blown stone removal method to separate and remove impurities like sandstone, metal blocks, and other crops including rice, wheat, soybeans, and coffee beans. More than 98% of stones are removed.

Dehusking, Paddy

This paddy contains rice that is protected by a coating known as husk. Paddy is cleaned to remove any dust that has adhered to it after being cut from the field. This paddy is subsequently brought to a rice mill for further processing.

The husk was once removed using two iron rolls moving at various speeds. These people were known as hullers. Paddy is infused in these two iron rolls, which then rub against one another to separate the rice from the husk.

The hardness of the rolls, however, meant that a significant portion of the rice was broken throughout the process, and in the current world, the price difference between full rice and broken rice is very large.

Purification of Rice

Rice whitening is the subsequent stage. as rice made using the aforementioned procedure has a layer of light brownish bran clinging to it. The bran layer of their rice must be removed to give it a highly pale hue because consumers prefer to buy and consume more and more white and brilliant coloured foods.

Contact us!

Products, systems, and services from Malik Agro Industries provide great added value and unique, expert solutions for agricultural equipment. The main hub of the Pakistan Agriculture Market, Lahore, is where Malik Agro Industries’ headquarters are located. inspire their clients and create a better future. Contact us at +92-332-4598173 or email us at info@malikagroindustries.co.